Let’s dissect garage floor coating system failures and understand how a true garage floor epoxy system could prevent it.

Imagine this scenario:

A Maryland homeowner, enticed by a 1-day floor coating company’s promise—“Our coatings are 4 to 20 times stronger than epoxy!”—opts for the quick installation. Initially, the floor appears flawless. But as Maryland’s humid summer transitions to a damp fall, issues emerge: bubbling, peeling, and delamination.

What went wrong?

Stage 1: Misleading Strength Claims

The claim of being “stronger than epoxy” often compares their product to low-grade, water-based DIY epoxy kits, not to professional-grade, 100%-solids garage floor epoxy systems.

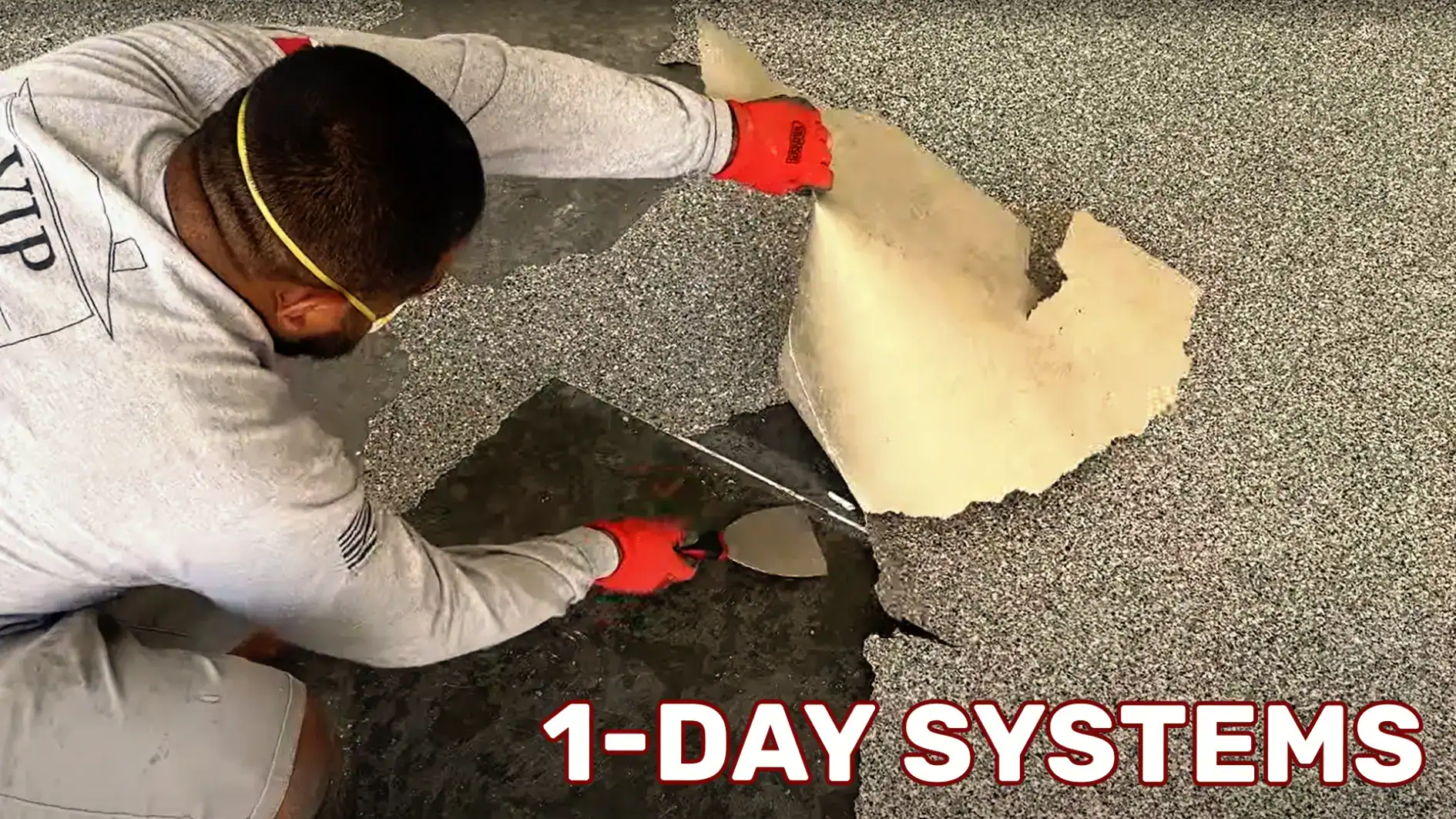

In reality, these 1-day systems typically use a polyurea or polyaspartic coating applied directly to the concrete. While these materials cure quickly, they lack the deep penetration and bonding strength of a properly applied epoxy base.

Stage 2: Absence of Moisture Mitigation

Maryland’s climate, characterized by high humidity and frequent rainfall, leads to moisture vapor rising through concrete slabs. Without a moisture-mitigating epoxy primer, this vapor can cause coatings to bubble and peel.

1-day installations often skip this crucial step, applying coatings directly to the concrete without addressing underlying moisture issues.

Stage 3: Thin, Rapid Application

To complete the job in a single day, these companies often:

- Apply a single, thin layer of coating

- Skip the second topcoat

- Neglect proper buffing of flakes

This rushed approach results in a coating that’s ill-equipped to handle Maryland’s environmental stresses.

Stage 4: Premature Failure

Without proper adhesion and moisture mitigation, the coating begins to fail:

- Bubbling due to trapped moisture

- Peeling from inadequate bonding

- Delamination under temperature fluctuations

The homeowner is left with a deteriorating floor and the realization that the “stronger than epoxy” claim was misleading.

The Solution: A True Garage Floor Epoxy System

At Garage Floor Coatings of Maryland, we prioritize quality over speed. Our 2-day installation process includes:

- A 100%-solids, moisture-mitigating epoxy primer that deeply penetrates the concrete, forming a strong bond and preventing moisture issues

- A full-flake broadcast for enhanced durability and aesthetics

- Two coats of 100%-solids polyaspartic topcoat for superior UV, chemical, and abrasion resistance

This comprehensive approach ensures a floor that withstands Maryland’s challenging climate and daily wear.

Don’t settle for shortcuts. Choose a garage floor epoxy system built to last. Contact us today for a free consultation and protect your garage floor investment.