When considering an epoxy floor coating in Maryland, it’s important to understand the terminology commonly used in the industry. Whether you’re looking to protect your garage floor or enhance the aesthetic of your basement, having a good grasp of these terms can help you make informed decisions. Let’s dive into the definitions in epoxy flooring and see how they apply to the unique climate and needs of Maryland homeowners and businesses. Because that way, you’ll be properly armed to find the concrete coating you need.

Definitions in Epoxy Flooring: Epoxy Coatings

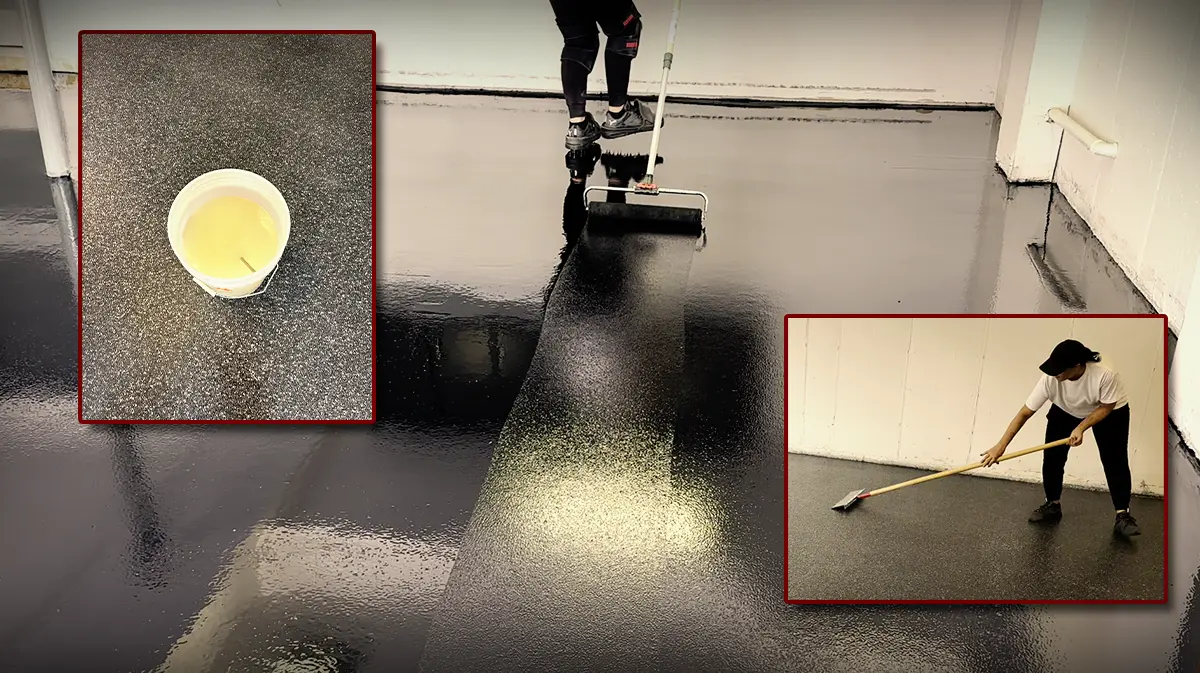

Epoxy coatings are slow-curing, “high-build” coatings known for their durability and resistance to chemicals, moisture, and abrasion. They are an excellent choice for a wide range of applications in Maryland. An epoxy coating is created when a resin (Part A) and hardener (Part B) are mixed together and a chemical reaction ensues. Because epoxies cure far slower than e.g., a polyurea-polyaspartic, they have time to deeply penetrate and bond with the concrete substrate. Hence, they’re excellent primer (direct-to-concrete) coatings, as long as they’re covered by a subsequent coating or flakes. Because they tend to fade and amber when exposed to UV light, they are not well-served as exterior color coats or topcoats (but excellent for interior spaces). Given Maryland’s variable weather, including cold, wet winters, epoxies are the best option as moisture-mitigating primer coats (they act as vapor barriers).

Definitions in Epoxy Flooring: Polyaspartic Coatings

Another high-performance coating is a polyaspartic (it’s an aliphatic polyurea). Like epoxy, a polyaspartic is a two-part mixture. However, polyaspartics (and polyureas), cure very fast! They also offer superior UV and chemical resistance, preventing yellowing or fading in areas exposed to sunlight. Perfect as top coats for Maryland’s outdoor garages or patios. Additionally, polyaspartics offer more flexibility in terms of application temperature, allowing for installations even in colder weather, which can be a challenge during Maryland’s winter months. However, polyurea-polyaspartics cure so quickly that they are poor primer coats, especially in the presence of moisture (whereby the cure even faster!). They simply don’t provide sufficient time (or thickness) to deeply penetrate the concrete substrate.

Definitions in Epoxy Flooring: Polyurethane Coatings

Polyurethanes are an older technology. They’re often used as a color coat or topcoat over epoxy primer coats, especially for exterior installations. This flexible layer provides excellent protection against UV rays, abrasions, and chemicals. In areas of Maryland where sunlight can be intense (i.e., exterior spaces), polyurethanes help to prevent discoloration or degradation over time. However, some polyurethane’s can be odorous and they don’t protect against “hot-tire” transfer (plasticizer migration)…so they are not to be used in any space where vehicles are parked.

Casual Terms Used by Homeowners

Homeowners in Maryland often use more casual terms when referring to epoxy or polyaspartic coatings, especially when talking about protective floor solutions for their garages or basements. A common phrase is garage floor coating, which usually refers to the application of layered epoxy, polyurethane, and/or polyurea-polyaspartic coatings to protect the floor from damage. This term is often used interchangeably with concrete paint, though the two are quite different. While some homeowners might refer to their epoxy floor as “paint,” true epoxy coatings bond to the concrete, providing significantly more durability and protection than any standard paint. It’s a common misconception, but an important one to clarify when considering options for long-term durability.

Maryland’s humid summers and snowy winters make waterproofing especially important for basements, which leads to another frequently used term: waterproofing basement. Epoxy coatings are commonly applied in basements to prevent moisture infiltration. By creating a seamless, moisture-resistant barrier, epoxy prevents water from seeping through cracks in the concrete and damaging the structure of the home. This is a particularly important consideration in Maryland, where rainfall can be significant, and basements are prone to flooding.

What’s Inside: Ingredients and Components

The strength of epoxy and polyaspartic coatings comes down to their key ingredients. Resin is the base component of epoxy, providing the liquid form that, once cured, creates a hard, durable surface. When combined with the hardener, the chemical reaction forms a bond that adheres to the concrete, making the floor resistant to damage from chemicals, water, and impact. This bond is what sets epoxy coatings apart from simpler floor coverings like concrete paint, which sits on the surface rather than becoming part of it.

Mica flakes are often added to epoxy or polyaspartic floors for both aesthetic and functional purposes. These natural mineral flakes create a shimmering finish that adds visual depth to the floor. In Maryland, mica flakes are popular for adding a high-end look to garages, basements, and commercial spaces. Not only do mica flakes enhance the floor’s appearance, but they also increase slip resistance, which is particularly beneficial in wet or high-traffic areas.

Conclusion

Epoxy and polyaspartic flooring systems provide Maryland homeowners with durable, aesthetically pleasing solutions for their garages, basements, and commercial spaces. By understanding the key terms, you’ll be better equipped to choose the right floor coating for your needs. Whether you’re protecting against Maryland’s humid summers or snowy winters, these flooring options ensure long-lasting durability and style.