When you’re comparing garage flooring options, the terminology can get technical fast—and some installers count on that. Learn the core terms the pros use, and you’ll instantly be able to spot quality, ask the right questions, and avoid shortcuts that lead to early coating failure.

Epoxy Coatings

Professionals rely on epoxy because it cures into a dense, highly adhesive material that bonds deeply to concrete. Used for primers and broadcast coats, a moisture-mitigating epoxy provides the strength and structural build that durable garage flooring systems depend on—especially important in Maryland’s moisture-rich climate.

Moisture Mitigation

Concrete always releases moisture vapor, and Maryland’s humidity only increases that risk. Moisture mitigation refers to the use of a thick, 100%-solids moisture-mitigating epoxy primer that creates a vapor barrier beneath the coating. Reliable 2-day systems include this step; fast 1-day systems often skip it, which can lead to bubbling or delamination.

Concrete Paint

Companies offering quick or low-cost solutions often use this term. Concrete paint doesn’t bond chemically with the slab and cannot handle hot tires, seasonal moisture, or freeze-thaw cycles. It’s decorative only—not true garage flooring—and it typically fails quickly in Maryland conditions.

Polyaspartic

A professional-grade clear topcoat known for UV stability, fast curing, and resistance to stains and chemicals. Pros use a 100%-solids clear polyaspartic to seal and protect the flake and moisture-mitigating epoxy layers beneath it. It’s excellent as a topcoat, but it is not a replacement for the epoxy primer coat—even if marketed that way.

Polyurethane

Another type of clear coat found in some flooring systems. While durable, polyurethane generally provides lower UV and chemical resistance than polyaspartic. For garages that see sunlight or fluctuating temperatures, polyaspartic is the preferred long-lasting finish.

Flake/Full-Flake

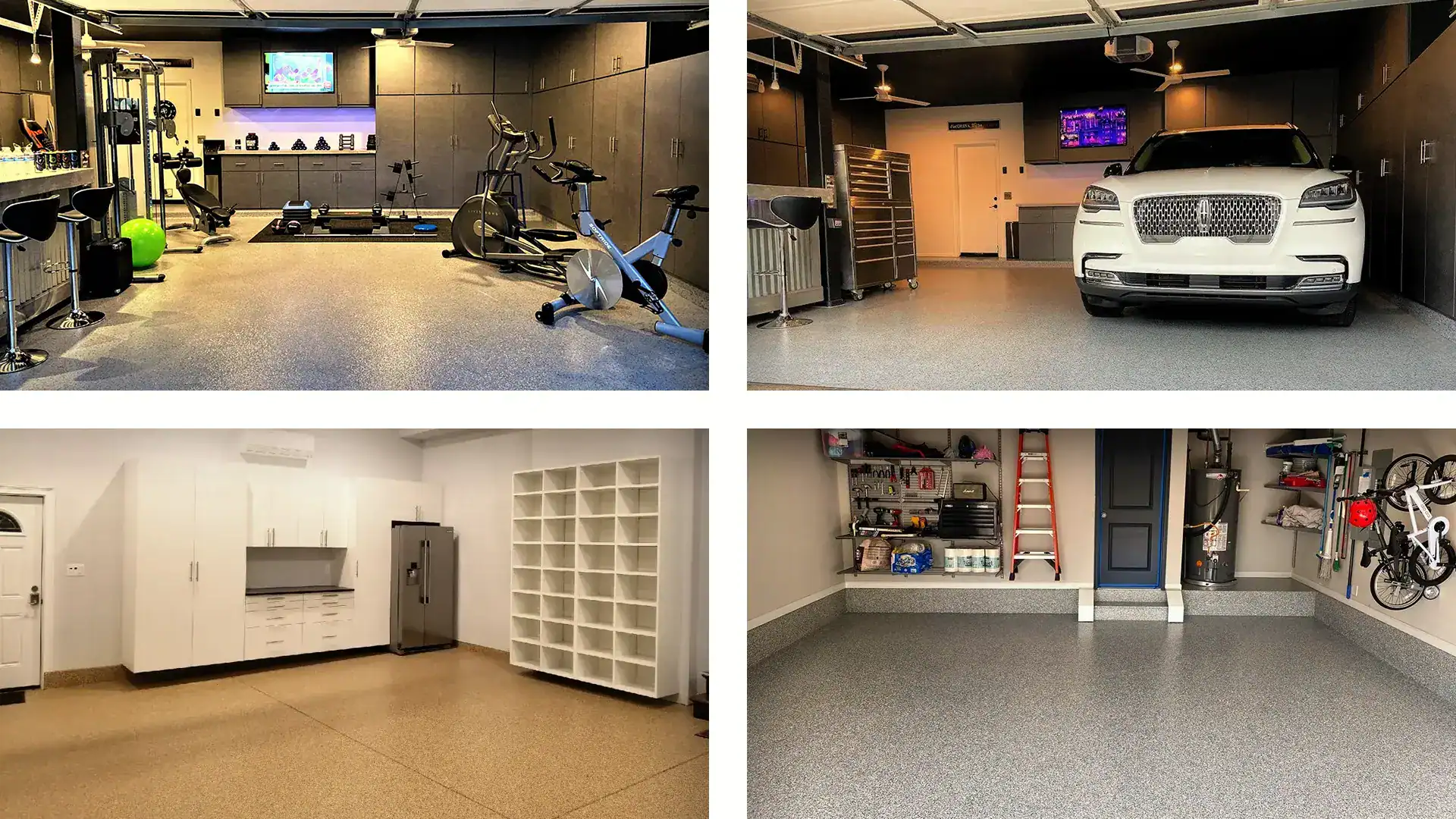

In a flake epoxy system, colored polyvinyl acetate (PVA thermoplastic) and/or mica mineral flakes are broadcast into the “wet” moisture-mitigating epoxy primer coat to add traction, color variation, and depth. A full-flake floor covers the entire primer surface, creating a thicker, more uniform finish with improved durability—ideal for high-use home garages.

Garage Floor Coating

When pros reference a garage floor coating, they mean a multi-layer system: moisture-mitigating epoxy primer, full-flake coverage, and 100%-solids polyaspartic topcoats. These layers work together to form long-lasting, seamless garage flooring that’s far more durable than paint or quick-cure solutions.

Ready for garage flooring designed to perform in Maryland’s climate? Garage Floor Coatings of Maryland installs premium systems built for durability and everyday use. Request your free quote today.