WE’RE FIGHTING BACK: THE TRUTH ABOUT 1-DAY SYSTEMS

An article written in August 2020 by GarageFloorCoating.com, describes the perils of “1-day” coating systems (Polyurea-Polyaspartic One-Day Systems: Do They Work). These garage floor coating systems are all the rage. Contractors love them because they’re easy and quick to install. And customers love them because the contractor is in-and-out in a single day. Caveat emptor (“Let the buyer beware”).

Seriously ask yourself, in the world of contractors…how often does “fast” mean “good”? In this blog, we’ll tell you the truth about 1-day systems.

What’s a Polyaspartic?

A polyaspartic is a 2-component, fast-curing “aliphatic polyurea” regularly used in the concrete coatings industry. It’s a fantastic product that, once applied, provides extreme UV, chemical and impact resistance. And if a quality 100% solids polyurea-polyaspartic is used, it can also prevent staining from “plasticizer migration” (tire staining) from parked cars. These products are excellent for use as color coats and durable clear topcoats.

However, polyurea-polyaspartics have an “Achilles heel”: they’re not meant to be applied as primer coats (that is, direct-to-concrete) because polyurea-polyaspartics don’t bond well to concrete in the presence of moisture. Because of this limitation, experienced (honest) contractors use a moisture-mitigating epoxy as the primer coat and a polyurea-polyaspartic as the clear top coat. Because the moisture-mitigating primer has a slower cure rate (at least, slower than a quick-cure polyurea-polyaspartic), the installation time typically spans up to 2 days…not 1.

“1-day” system contractors know this, so they: (1) trash-talk epoxy products to their potential customers, and (2) provide cover by adding a warranty exclusion in the contract against “moisture-related issues”. (Note: All coating product types, be they epoxies, polyurethanes, or polyurea-polyaspartics, should be used in a quality contractors’ arsenal…because each product type has its merits and its limitations).

Why Don’t “1-Day” Systems Warrant Moisture-Related Issues?

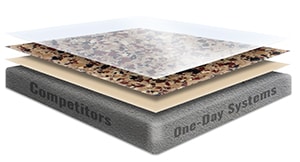

Because installers of “1-day” polyurea-polyaspartic coating systems use a thin coat of 70%-80% solids polyaspartic (not 100% solids) direct-to-concrete. Bad idea! Polyurea-polyaspartics aren’t meant for direct-to-concrete application because they fail where medium to high moisture vapor transmission is present. That is, they delaminate over time.

Lo and behold, when your “1-day” coating system does delaminate, the contractor simply invokes the warranty exclusion against “high-moisture conditions” (written in small print). Sneaky. So why do so many contractors hype “1-day” polyurea-polyaspartic coating systems? Because they use less product and only require 1 day of labor, which is very profitable…for the contractor of course.

If you know that ultra-thin “1-day” systems use half the coating material, don’t warrant “moisture-related issues”, and don’t warrant tire staining (or windshield wiper fluid, bleach or citrus products)…why are you investing in a concrete coating at all?

Us Versus Them

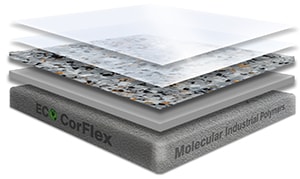

On the contrary, our thick garage floor coatings are guaranteed against moisture-related conditions and tire staining (and most automotive fluids). We have an entire line of industrial-grade polyurea-polyaspartic coatings…and we use them in every garage, as clear top coats only…two coats, by the way, not 1. Never as direct-to-concrete primers!

What also separates us from the pack is we use proprietary mica stone blends in our full-chip concrete coatings…not just thermoplastic…so our floors are thicker, stronger, and way better looking. Our full-chip, mica stone concrete coatings, like our Bagari SE and Vintage Mica series, incorporate an ultra-thick 100%-solids moisture-mitigating primer coat, a full-chip mica-infused broadcast, and two 100%-solids polyurea-polyaspartic top coats (with anti-skid to prevent slippage). This produces garage floor coatings over 35 mils thick and is why we can warrant against moisture-related issues and “hot tire transfer”…the #1 reasons for coating system failures.

Want stunning, industrial-grade, full-chip garage floor coatings with a real lifetime warranty? Call us or click here for your free estimate.