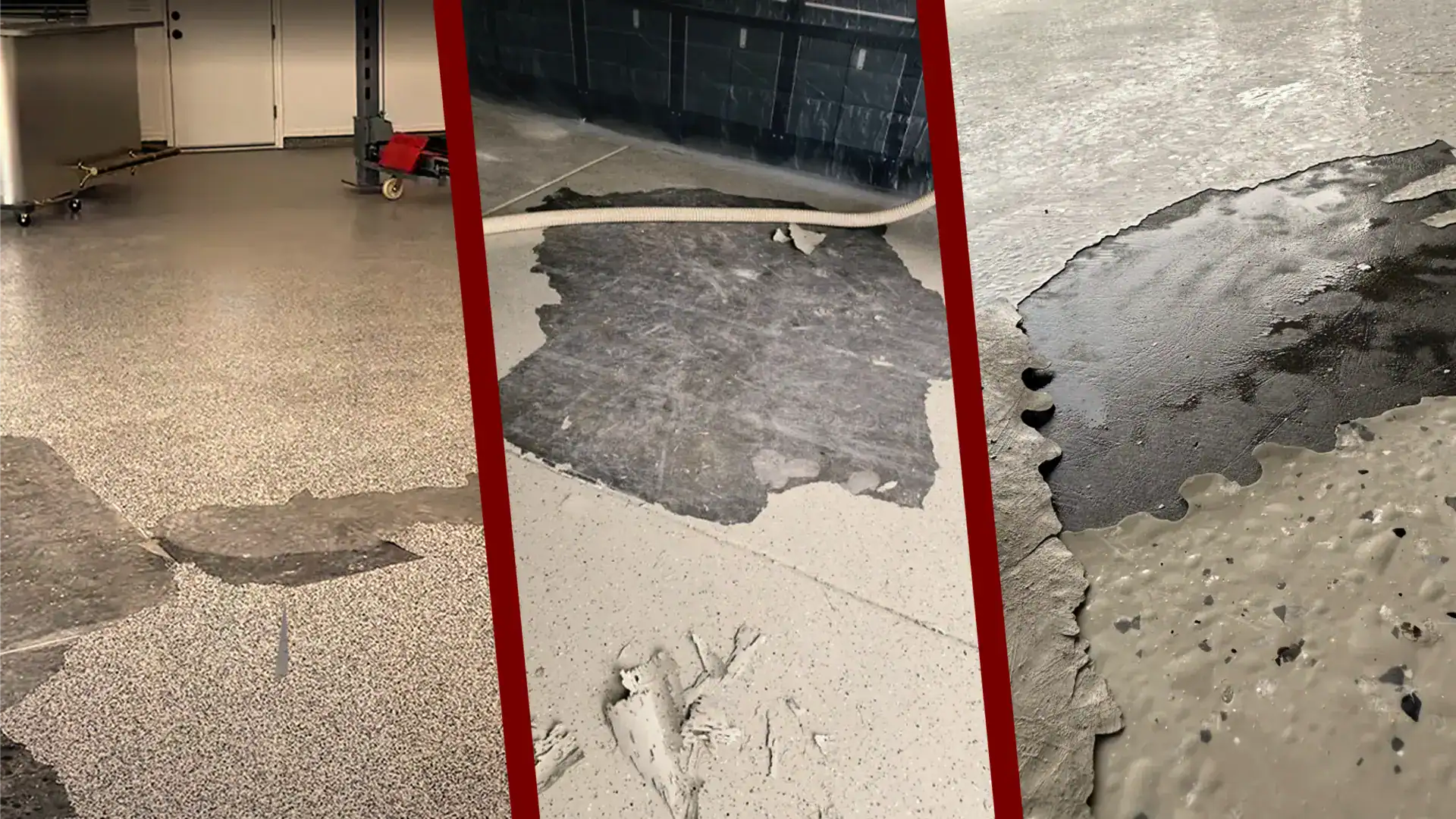

In Maryland, garage floor coating failures are often blamed on humidity, groundwater, or weather swings. But peeling and delamination are not surprises. With many 1-day polyurea installs, the outcome is predictable from the start.

The real issue is not unexpected conditions. It is installing a garage floor coating that was never engineered to handle moisture and then using a meter to shift blame after it fails.

How Predictable Polyurea Failures Get Rebranded as “Moisture Problems”

When a polyurea coating bubbles or releases, installers frequently point to a moisture meter reading taken after the failure. That reading is usually captured at the damaged area, where vapor pressure is highest, and used to deny the warranty.

What is missing is meaningful testing and documentation before installation. The moisture did not suddenly appear. It was present in the slab from day one, making the failure foreseeable when no moisture mitigation layer was included.

Why 1-Day Systems Fail the Same Way Every Time

A speed-driven garage floor coating typically relies on fast-curing polyurea or polyaspartic primers applied directly to concrete. These materials allow for a 1-day turnaround, but they do not block vapor or equalize slab pressure.

Fast cure does not equal durability. Without a moisture-mitigating base coat, Moisture Vapor Transmission pushes upward through the slab. In Maryland, rainfall, groundwater saturation, and seasonal humidity keep that pressure active year-round. When vapor meets a coating system that cannot manage it, blistering, peeling, and delamination follow a familiar pattern.

Why the Moisture Meter Appears Only After Polyurea Failure

If moisture meters were truly about prevention, they would be paired with systems designed to manage moisture. Instead, they often appear only after predictable polyurea failures occur.

The meter becomes a tool for rewriting the story. A known condition is labeled a defect, and responsibility shifts away from the system design.

How Our Garage Floor Coating Systems Prevent Predictable Failures

Garage Floor Coatings of Maryland installs garage floor coating systems designed to stop failure before it starts. First, we begin with an industrial, 100% solids moisture-mitigating epoxy primer. It acts as a moisture vapor barrier by creating a thick, chemically bonded foundation within the slab.

secondly, the customer-selected decorative flake blend is broadcast into the primer coat across the entire floor for texture and strength. Finally, on day 2, dual 100%-solids polyaspartic clear topcoats are applied for abrasion resistance, UV stability, and easy maintenance. This professional 2-day installation ensures each layer performs as intended.

Before making a decision, explore colors and flake blends using our Live Coatings Visualizer. Then schedule a consultation with Garage Floor Coatings of Maryland and choose a system built to prevent predictable problems, not explain them away.